Battery Process

More Custom Items

Xiaowei New Energy

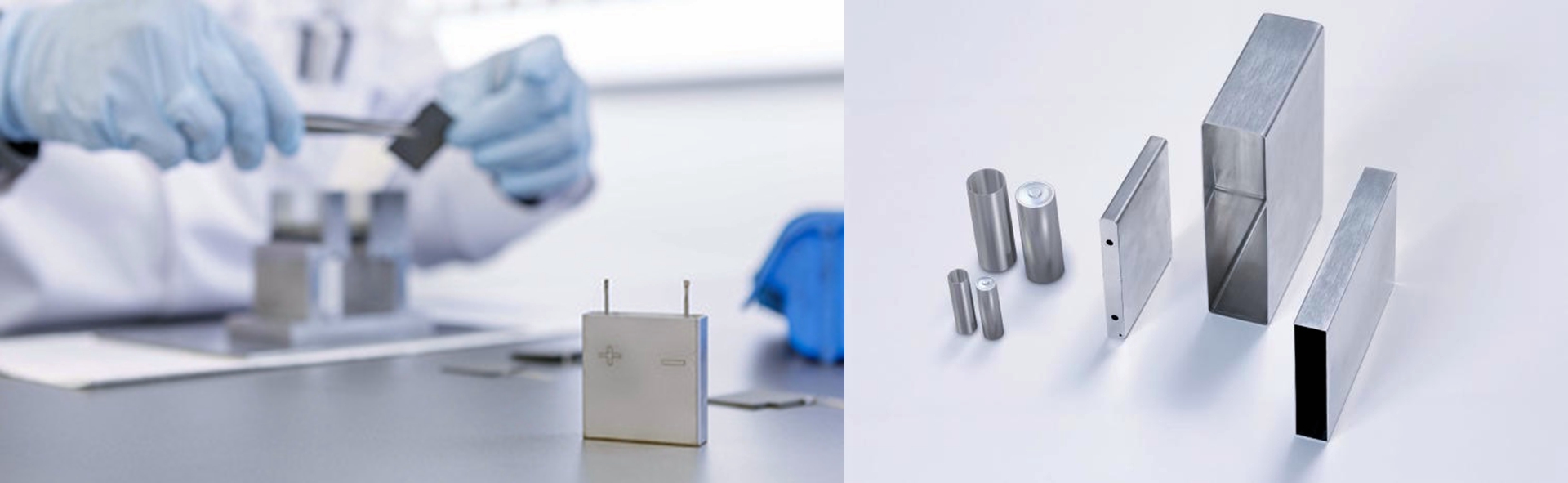

Battery Materials,Laboratory Cell Battery Research Equiment,Cell Battery Pilot Line, Cell Battery Production Line for Coin Cell,Cylindrical Cell,Pouch Cell,Prismatic cell. We supply Lithium ion battery material machinery and equipment, sodium ion battery material machinery and equipment, lithium metal battery material machinery and equipment, lithium sulfur battery material machinery and equipment, solid/semi-solid battery material machinery and equipment.

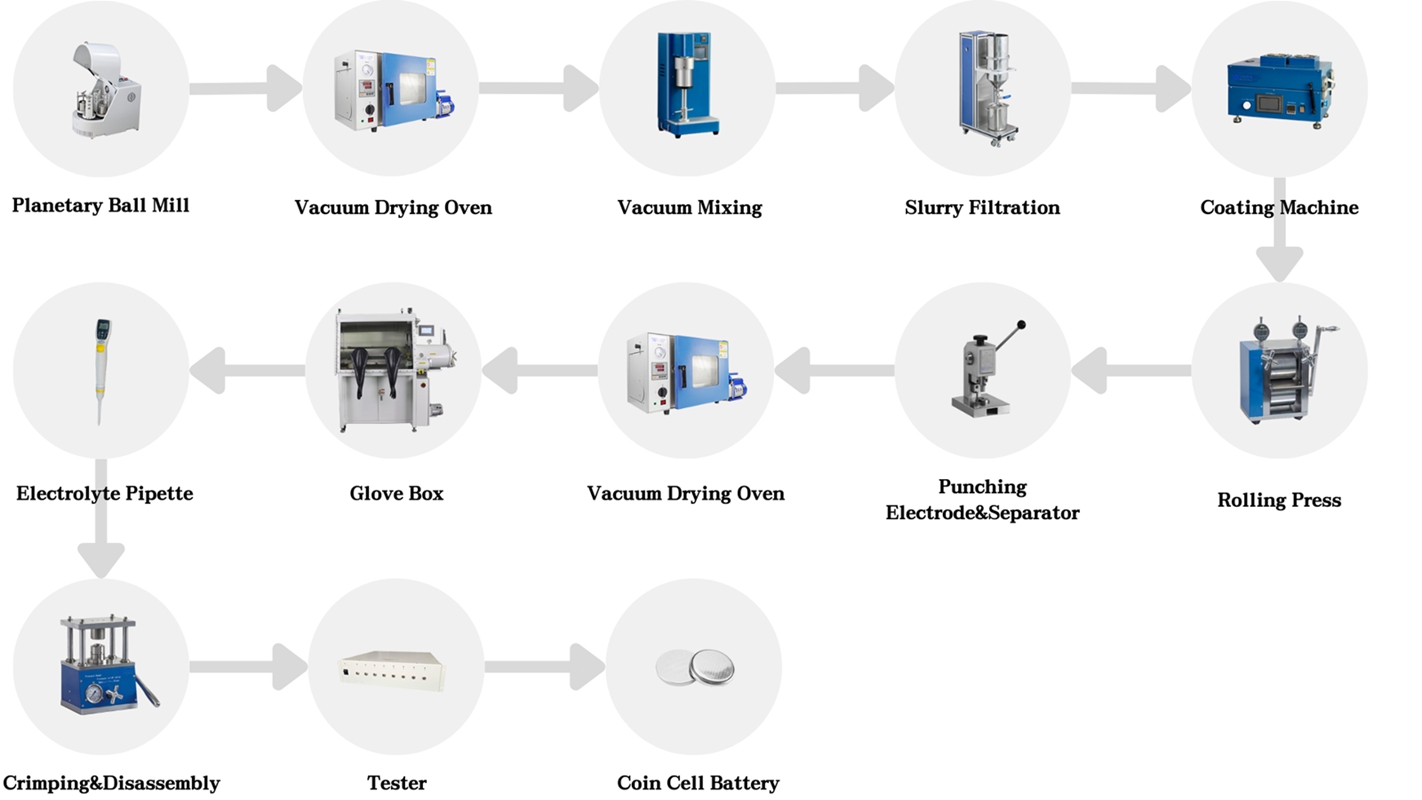

Coin Button Cell Battery Laboratory Equipment

Coin Cell Research Process

Front stage process: Plantary Ball Mill Machine,Vaccum Dying Oven,Vacuum Mixing Machine

Middle stage process: Slurry Filtration,Coating Machine,Roller Press Machine,Punching Electrode Separator Machine

Final stage process: Vacuum Drying Oven,Glove Box,Electrode Pipette, Crimping Sealing&Disassembly Machine, Battery Test Machine.

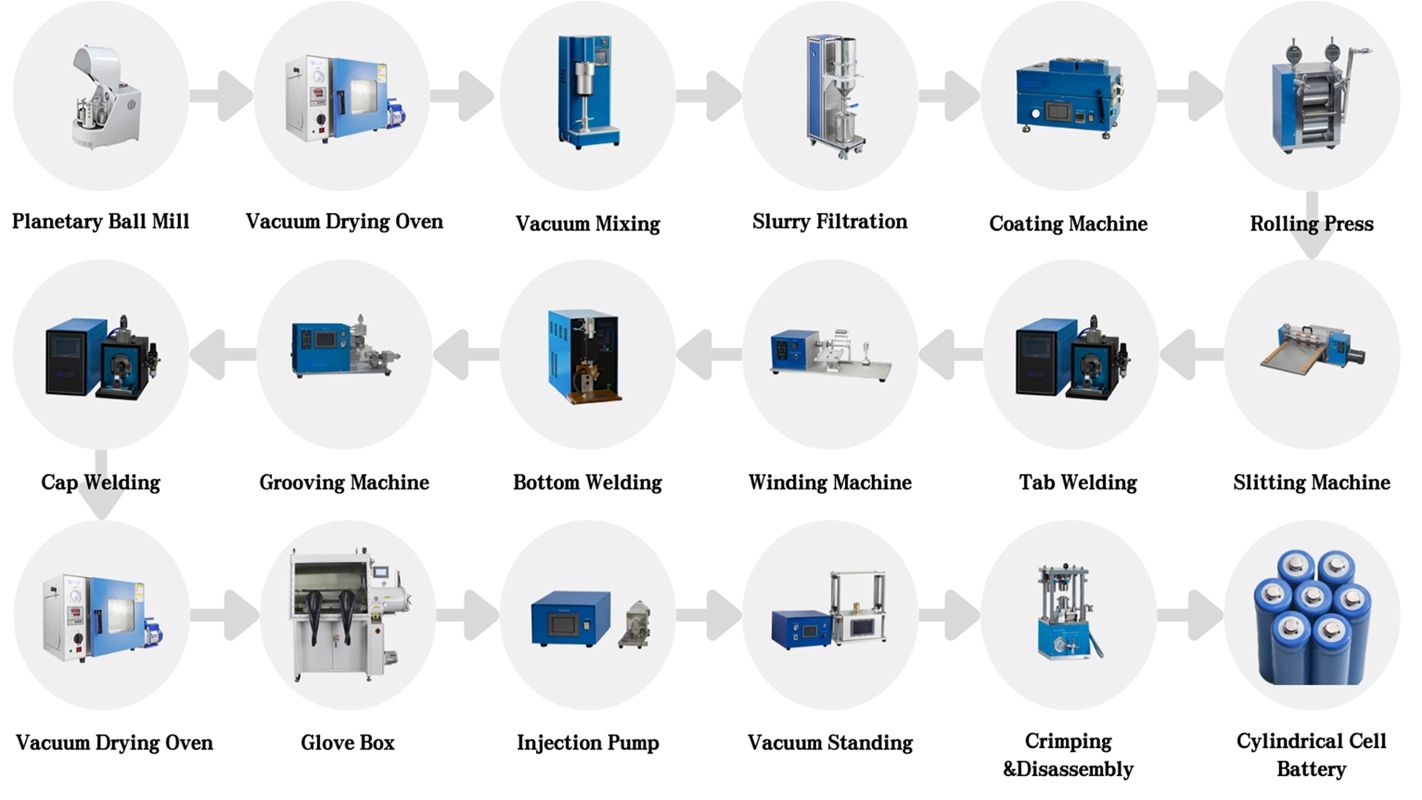

Cylindrical Cell Battery Laboratory Equipment

Cylindrical Cell Research Process

Front stage process: Plantary Ball Mill Machine,Vaccum Dying Oven,Vacuum Mixing Machine

Middle stage process: Slurry Filtration,Coating Machine,Roller Press Machine,Slitting Machine, Tab Welding Machine, Winding Machines, Bottom Spot Welding, Grooving Machine,Cap Welding

Final stage process: Vacuum Drying Oven,Glove Box,Electrode Injection Pump,Vacuum Standing Machine,Crimping Sealing&Disassembly Machine, Battery Test Machine.

Pouch Cell Battery Laboratory Equipment

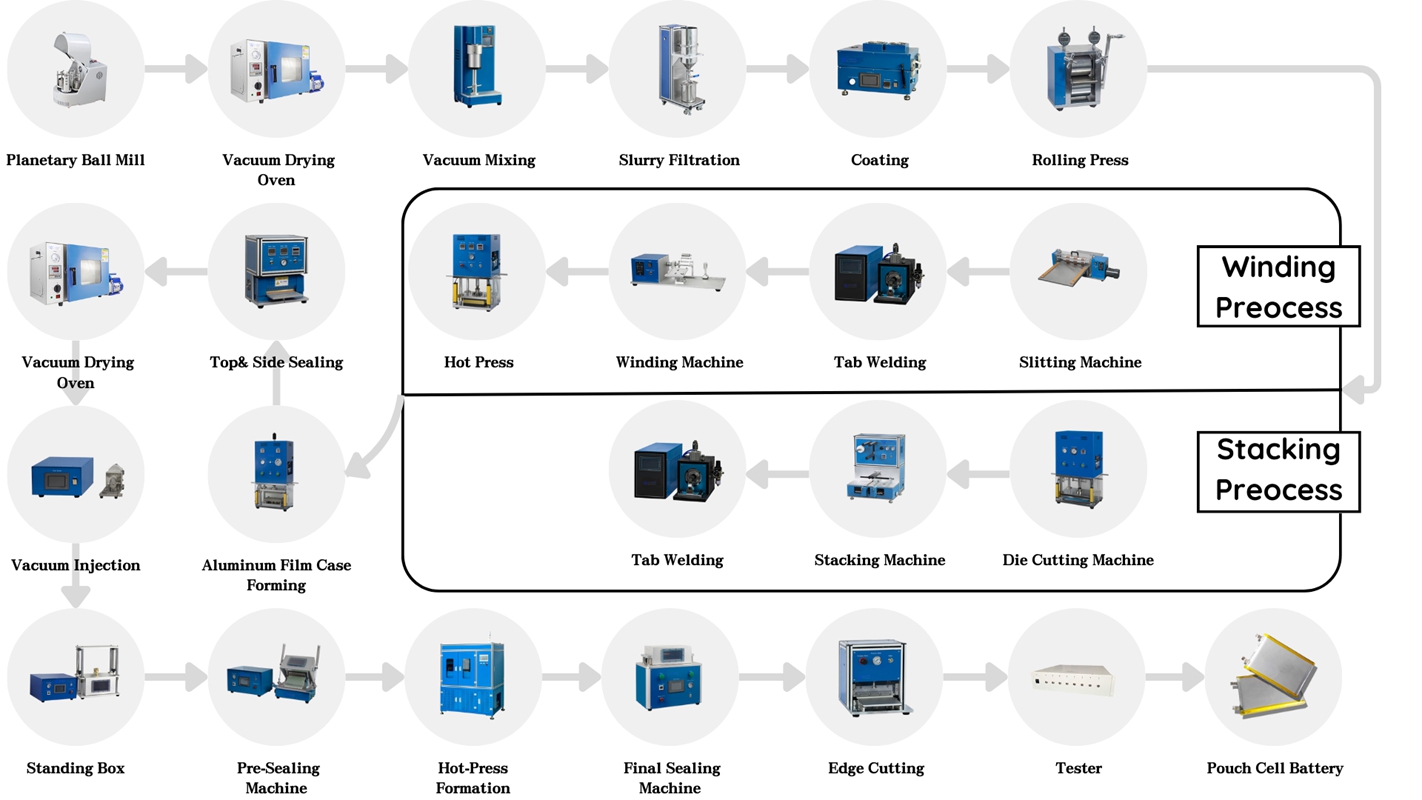

Pouch Cell Research Process

Front stage process: Plantary Ball Mill Machine,Vaccum Dying Oven,Vacuum Mixing Machine

Middle stage process(Winding&Stacking): Slurry Filtration,Coating Machine,Roller Press Machine,Slitting Machine, Tab Welding Machine, Winding Machines,Hot Press Machine, Top&Side Sealing Machine, Die Cutting Machine,Stacking Machine,Tab Machine,Aluminum Film Case Forming Machine

Final stage process: Vacuum Drying Oven,Glove Box,Electrode Injection Pump,Vacuum Standing Machine,Pre-Sealing Machine, Hot Press Machine,Edge Cutting, Battery Test Machine.