——Dr.Xu/Mr.Jin/Mr.Link

Service Purposes

Xiaowei Team will try our best to do all the work and after-sales service for our customers. We also believe that the service value of all things is far greater than the value of equipment. For customers, the profit point that our team will help you is far greater than the equipment, which is also the advantage of our company and team.

Let the customer satisfaction, is the purpose we have been pursuing!

Xiaowei Team

Battery Production Machine Supplier – Xiaowei New Energy

Application Industry

Research materials

POWER ENERGY

Energy storage

Battery Process

More Custom Items

Xiaowei Profile

Specialize in cell equipment manufacturing for more than 20+ years.

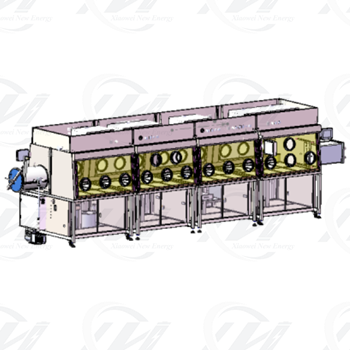

Guangdong Xiaowei New Energy Technology Co., Ltd is a Turnkey Company and manufacturer specializing in the manufacturing of cell Battery equipment.

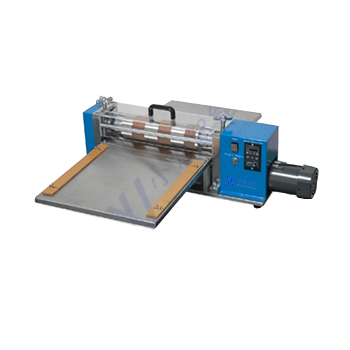

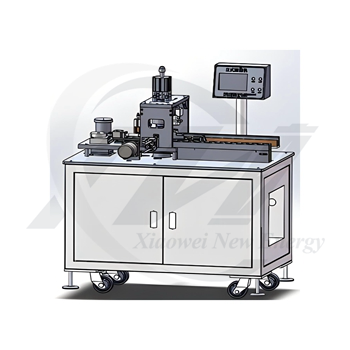

Such as Coin Cell manufacturing process flows equipment, Cylindrical Cell manufacturing process flows equipment, Pouch Cell manufacturing process flows equipment, Prismatic cell manufacturing process Various shapes of battery production machine such as flows equipment.

Xiaowei Equipment

Xiaowei engineers and technicians have 20 years of experience in battery manufacturing industrial automation equipment design and cell manufacturing(battery Production machine). We have been focusing on providing customers with first-class high-tech products and high-quality battery equipment services, and have been widely recognized by many well-known domestic and overseas companies and applications.

Xiaowei relies on South China University of Technology(SCUT), and the core team is composed of several doctors and masters from SCUT. And Xiaowei has designed and developed a variety of advanced cell materials and customized battery equipment for China’s top battery research institutes and well-known battery factories.