Electrode slurry preparation and pole piece(electrode) coating are undoubtedly the most basic and critical processes in lithium battery electrode manufacturing, and the properties of electrode slurry directly affect the efficiency and quality of coating.

In the production of lithium-ion batteries, 1-electrode manufacturing, 2-battery cell assembly and packaging, and 3-battery precharging and activation are the three main work stages, which are what the lithium battery population calls front workers, middle workers, and back workers. Electrode manufacturing is the flesh and blood of the production of lithium batteries, cell assembly and packaging shapes the skeleton of the lithium battery, and precharging and activation of the lithium battery molds its soul. The three are closely interdependent and indivisible wholes. In the lithium-ion battery production process plays an important role in both. Slight defects in any of these factors, such as raw materials, battery design, manufacturing equipment and processes, environment, etc., may lead to poor battery product performance.

In the pole piece manufacturing process stage, it can be subdivided into five processes: 1-slurry preparation, 2-slurry coating, 3-pole piece rolling, 4-pole piece slitting, and 5-pole piece drying. Of course, depending on the manufacturing process, each company and manufacturer will change or delete some of the process sequences. Electrode slurry preparation and pole piece coating are undoubtedly the most basic and critical processes in electrode manufacturing, and the properties of electrode slurry directly affect the efficiency and quality of coating.

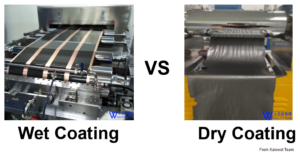

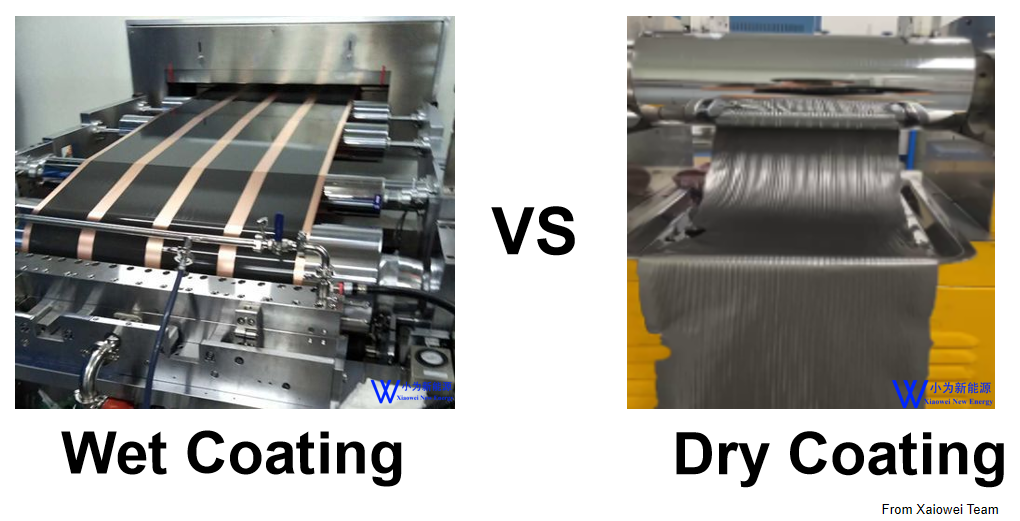

Lithium battery slurry is divided into positive and negative electrode slurries. The active materials, conductive agents, binders, solvents, etc. used in the two slurries vary with the battery system. The preparation of positive and negative electrode slurries includes a series of processes such as mutual mixing, dissolution, and dispersion of liquids and liquids, liquids and solid materials, and this process is accompanied by changes in temperature, viscosity, environment, etc. Regardless of whether a water-based system or an oil-based system is used, the current mixing processes used by lithium battery manufacturers are mainly divided into two types: wet process and dry process. Let’s analyze the two mixing processes:

1.Wet pulping process

The difference between wet pulping and dry pulping processes is mainly reflected in the difference in solid content of slurry at different stages. The characteristic of the wet pulping process is that the solid content of the final slurry is low in the early stage, while the dry pulping process is just the opposite.

The main process of wet pulping is to first mix and stir materials such as binders and conductive agents, then add active substances for full mixing and dispersion, and finally add an appropriate amount of solvent to adjust the viscosity to suit coating. The binder is mainly in powder and gel form. Some companies will first make it into glue, which facilitates the effectiveness of the binder. Some companies directly use powder binder. The selection of the binder state of the positive and negative electrodes also depends on the situation. For example, for the commonly used positive electrode binder PVDF, it is not recommended to use powder directly for higher molecular weights, but should be made into a glue first and then slurry. Material preparation. The dissolution of PVDF requires at least 2-3 hours under normal temperature and pressure to completely dissolve. Otherwise, the viscosity of the slurry will fluctuate greatly, which will also have a great impact on the change in surface density during coating. The wet pulping process is widely used by Chinese lithium battery manufacturers.

In the wet mixing process, the dual planetary vacuum mixer is generally selected as the mainstream lithium battery slurry mixing equipment. The characteristics of the wet pulping process are that the uniformly dispersed conductive adhesive is first prepared, and then the active material and the conductive adhesive are mixed and dispersed. This process takes a short time, is relatively simple, and has good slurry fluidity and fewer bubbles. The mixing time is short, which is beneficial to improving production efficiency. This process has strong adaptability and is acceptable even when there are small quality differences in active materials, conductive agents, etc. The prepared slurry will not affect the existing coating process and pole piece quality. In addition, the time required for later vacuuming of the slurry is short. However, the problem with the wet stirring process is that due to the large surface area of the conductive agent, it is easy to absorb the solvent, resulting in poor fluidity of the solvent. After adding the active material, it is difficult to achieve a uniformly dispersed state. Under the same solid content conditions, the viscosity of the slurry is higher than that of the dry pulping process.

2. Dry pulping process

The process of dry pulping is to first premix powder materials such as active substances and conductive agents at a certain speed. After mixing, add the binder, mix and stir, gradually add the solvent for mixing and dispersion, and finally add a certain amount of solvent to dilute and adjust to the viscosity required for coating. In the dry pulping process, the mixing and dispersing process of lithium-ion battery slurry can be divided into a macro-mixing process and a micro-dispersion process. These two processes are always accompanied by the entire process of lithium-ion battery slurry preparation. The dry pulping process can be visually represented by the following diagram: Dry Coating Machine

①Mix dry powder. During the dry powder mixing stage, the material particles are in contact with each other in the form of points, points, surfaces, and points. The contact forms are different depending on the type of material. At this stage, the internal porosity of the material is high, the friction on the surface of the powder is small, and most materials can be mixed and contacted in a short period of time.

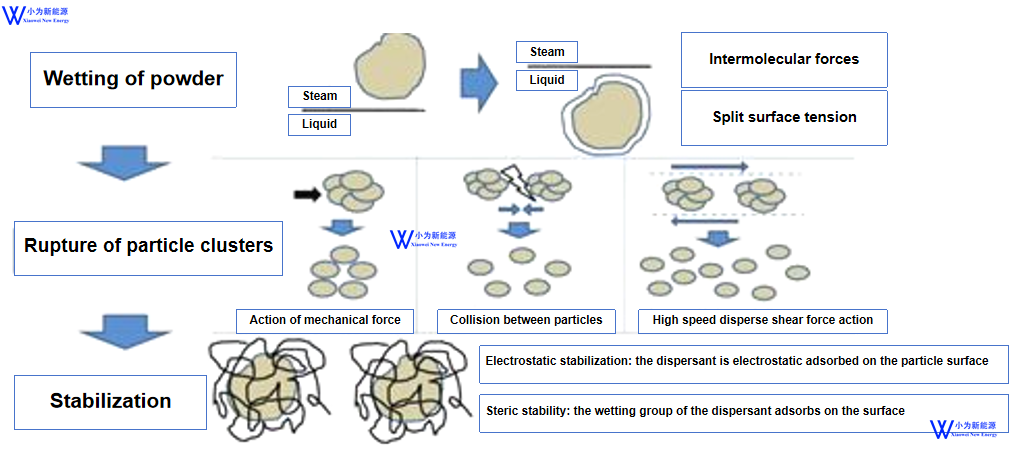

②Material wetting and mixing stage. At this stage, after the dry powder is mixed evenly, the binder liquid or solvent is added, and the raw materials are moistened and become muddy. After strong stirring by the mixer, the material is sheared and rubbed by mechanical force. At the same time, there will be internal friction between the particles. Under each force, the raw material particles tend to be highly dispersed. This stage has a crucial impact on the particle size and viscosity of the finished slurry.

③Dilution and dispersion stage. After the second stage is completed, the solvent is slowly added to adjust the viscosity and solid content of the slurry for further dispersion. At this stage, dispersion and agglomeration coexist, and finally reach stability, and the slurry forms a stable suspension state. At this stage, the dispersion of materials is mainly affected by mechanical force, friction resistance between powder and liquid, high-speed dispersion shear force, and impact interaction force between slurry and container wall.

The difference between the dry pulping process and the wet process is that in the second stage, there is a large internal friction between the materials and between the equipment and the materials. Under the action of various forces, the materials can achieve a good dispersion state. The high degree of slurry dispersion is beneficial to the quality of the pole piece. Under the same solid content, the viscosity of the slurry prepared by dry method is lower. The lower the viscosity of the slurry, the shorter the time it remains stable and the easier it is to separate. The slurry easily settles at the corners during the coating process, causing settlement and causing fluctuations in coating accuracy. Secondly, it is difficult to control the optimal state of materials in the dry pulping process. As raw material particle size, pH value, specific surface area and other factors change, the solid content in the optimal state will change and the process needs to be readjusted. It will affect production efficiency and consistency between different batches of pole pieces.

Above, the wet pulping process and dry pulping process are summarized.

More about: Solid-state battery technology using dry pulping process – Xiaowei